-

Orbital 3000 Triple

This page shows many beneficial and unique features of VFSI's Orbital 3000 Triple. Take a look and see why VFSI's Orbital 3000 Triple excels in performance, reliability, and durability.

The Orbital 3000 Triple shaker weighs 13000 pounds and is 130.5" long and 270" wide. The vibrators extend another seven inches on each side. The 30-1/2" weir height is one of the lowest in the industry. Weir height for 27-1/2" are available on request, allowing placement on rigs with limited bell nipple-to-pit drop.

Click to view the Orbital 3000 Triple specification sheet. |

The Orbital 3000 Triple uses orbital motion for extended screen life and excellent conveyance. The large screen area of 90 ft2 and high g forces of 6.9 g’s result in exceptional performance. Shaker performance can be characterized by the product of screening area and g's. The Orbital 3000 run at 6.9 g's (7.5 g's optional), provides 540 ft2-g's. This is one of the largest performance ratings in the industry.

All baskets are fully seal welded and stress relieved. Seal welding reduces corrosion, adding years to machine life. The Orbital 3000 pretension screening machine requires minimal maintenance, even in oil based muds.

Two layers of powder coat. Baked on zinc-rich epoxy first coat provides corrosion resistance. Final coat provides abrasion resistance. Most fasteners are stainless steel, providing excellent corrosion resistance.

The Orbital 3000 is exceptionally quiet, due to efficient isolation, orbital motion and a sturdy base. With the machine running, it is possible to stand a nickel on edge at each corner of the machine.

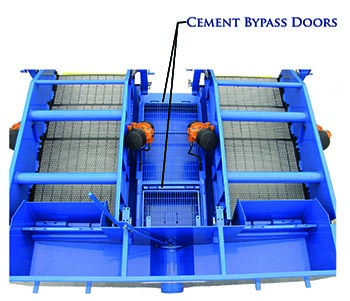

The VFSI Orbital 3000 Triple shaker is conveniently arranged to simplify drilling fluids/cement bypass management.

Normal Operation: |

In normal drilling operations, the door through the floor pan between the Orbital 3000 baskets returns flow to the sand trap. |

|

Cementing Operation: |

Cement is diverted to bypass the Orbital 3000 baskets by installing the floor pan door and the two inner shaker doors. Removing the two cement bypass doors and opening the bypass gate discharges cement to the reserve pit. |

|

The grated area between the baskets provides a clean walkway to service the shaker.

Movement of flow is provided by sliding gates on both sides of each basket. Gate hangers are conveniently provided between the two baskets. Gate hangers are also provided on the back side of the possum belly.

Single-motion linkage allows the bypass gate to be opened easily and quickly; the handle is visible to flag the operator about gate condition.

Below are some of the benefits of Vortex Fluid Systems Orbital 3000 shaker.

90 ft2 of screening area |

high performance |

competitively priced |

dependable and durable |

low maintenance |

convenient cement bypass |

minimal operational costs |

simplification of rig move |

low weir height |

vibration isolation |

minimal noise |

simple to adjust screen angle |

Stainless steel spring isolators provide superior isolation and corrosion resistance. An Orbital 3000 resting on flat concrete will not “walk”.

By adjusting a short pipe within the flow distributor, flow is spread evenly across the basket.

The Italvebras vibrators are exceptionally durable. The Italvebras vibrators are capable of delivering 6.9 g’s of vibration to the Orbital 3000.

The angle of the screen basket can be adjusted from 1 to 5 degrees from either side using a hand crank.

An Orbital 3000 Triple simplifies rig moves by allowing the user to simply disconnect the flow line and pick up the shaker by four lift eyes located between the baskets. Due to proper weight distribution, the Orbital 3000 Triple remains level when hoisted.

Durable polyurethane wedge blocks hold screens securely in place. Manufactured with a steel insert for increased rigidity.

The explosion proof electrical box is powder coated, has an “O” ring seal on the door and rubber boots on the switches. Customer wiring consists of hooking power to the terminal strip.

Possumbelly gates are provided to divert flow from each basket. These gates during cementing operations can also be used to keep cement out of the baskets.

The Orbital 3000 comes with a tool box. This box contains equipment for operation and basic maintenance of the Orbital 3000 shakers and Italvebras vibrators.

wedge block installation tool |

vibrator grease |

allen wrench set |

1/4" metric deep socket set |

extra isolator |