-

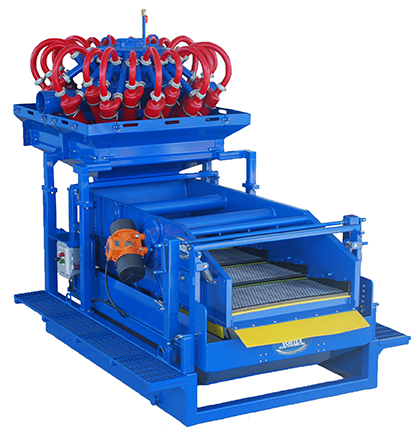

Orbital Industrial

Industrial shakers are used in many different industries. Vortex is proud to offer many different shaker configurations for industrial facilities. This page shows many beneficial and unique features for VFSI's Industrial shakers. Look and see why VFSI's shakers excel in performance, reliability, and durability.

Because of the wide range of industrial shaker applications Vortex Fluid Systems offers multiple shaker sizes from a 3, 4, and 5 panel industrial shaker. A wide range of mounting configurations are also possible. Vortex Fluid Systems is committed to serving our customers' needs by producing unique shaker configurations when requested.

The Orbital Industrial shaker uses elliptical motion for extended screen life and excellent conveyance. The large screen area of 30 ft2 and high g forces of 6.9 g’s (7.5 g's optional) results in exceptional performance. Shaker performance can be characterized by the product of screening area and g's. The Orbital 3000 runs at 6.9 g's (7.5 g's optional), provides 188 ft2-g's. This is one of the largest performance ratings in the industry.

All baskets are fully seal welded and stress relieved. Seal welding reduces corrosion, adding years to machine life. The Orbital pretension screening machine requires minimal maintenance, even in oil based muds.

Two layers of powder coat with a baked on first coat that provides corrosion resistance. The final coat provides abrasion resistance. Most fasteners are stainless steel, providing excellent corrosion resistance.

The Orbital industrial shaker is exceptionally quiet, due to efficient isolation, orbital motion and a sturdy base. With the machine running, it is possible to stand a nickel on edge at each corner of the machine.

Below are some of the benefits of Vortex Fluid Systems Orbital Industrial shakers.

37.5 ft2 of screening area |

high performance |

competitively priced |

dependable and durable |

low maintenance |

minimal operational costs |

vibration isolation |

minimal noise |

simple to adjust screen angle |

The Orbital Industrial comes with a tool box. This box contains equipment for operation and basic maintenance of the Orbital Industrial shakers and Italvibras vibrators.

wedge block installation tool |

vibrator grease |

allen wrench set |

1/4" metric deep socket set |

extra isolator |

The explosion proof electrical box is powder coated, has an “O” ring seal in the door and rubber boots on the switches. Customer wiring consists of hooking power to the terminal strip.

Stainless steel spring isolators provide superior isolation and corrosion resistance. An Orbital Industrial resting on flat concrete will not “walk”.

The Italvibras vibrators are exceptionally durable and capable of delivering 6.9 g’s of vibration (7.5 g's optional) to the Orbital Industrial.

The angle of the screen basket can be adjusted from 1 to 5 degrees from either side using a hand crank.